1. Perfect fusion of technology and nature

The production of bamboo fiber Tencel quilt begins with strict raw material screening. Bamboo fiber is taken from four-year-old high-quality bamboo, and pure bamboo pulp is extracted through multiple processes such as crushing, steaming, and grinding. Tencel fiber uses eucalyptus wood from sustainably managed forests and is made into wood pulp through advanced technology. Both raw materials have passed FSC forest certification to ensure the sustainability of the source.

In the production process, a unique two-component spinning technology is used. Bamboo pulp and wood pulp are mixed in a scientific ratio, impurities are removed through a nano-level filtration system, and then a solvent spinning process is used to make composite fibers. This process ensures that the two fibers are perfectly combined at the molecular level, retaining the natural characteristics of bamboo fiber and the excellent quality of Tencel.

Environmentally friendly production technology is reflected in every link. Using a closed-loop production system, the organic solvent recovery rate reaches 99.7%, and the wastewater is purified through multiple purification processes to meet drinking standards. The entire production process achieves zero pollution emissions, and each ton of fiber produced can reduce carbon emissions by 60%.

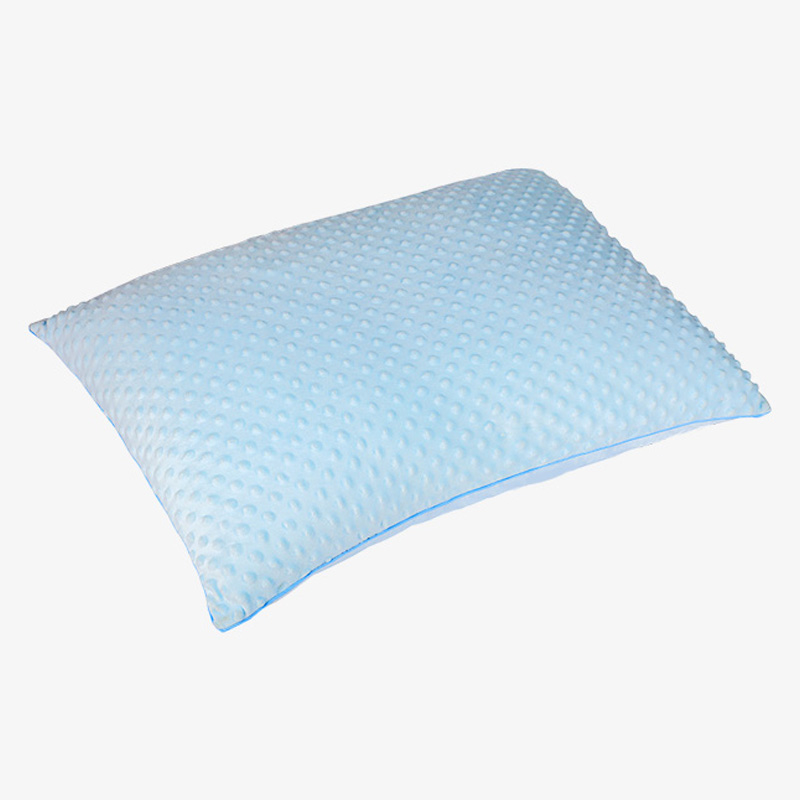

2. Excellent product characteristics

The bamboo fiber Tencel quilt has a unique physical structure. Under an electron microscope, the fiber surface is covered with nano-scale micropores, which form a natural temperature regulation system. The fiber cross-section is a plum blossom-shaped structure, which increases the specific surface area and enhances the moisture absorption and perspiration function.

Functional test data show that the air permeability of the bamboo fiber Tencel quilt is 3.2 times that of ordinary cotton quilts, and the moisture absorption rate is 35% faster than that of pure cotton. Under an environment with a temperature of 20°C and a humidity of 65%, the humidity of the quilt can be maintained in the optimal range of 45%-55%.

3. The value of multiple advantages

From an environmental protection perspective, the entire life cycle of the bamboo fiber Tencel quilt embodies the green concept. The raw materials are renewable, the production is low-energy, no special care is required during use, and it can be naturally degraded after being discarded. A bamboo fiber Tencel quilt can reduce carbon emissions by about 15 kilograms throughout its life cycle.

Significant health benefits. The natural antibacterial properties reduce the breeding of dust mites, which is especially suitable for people with allergies. Good temperature and humidity regulation functions help improve sleep quality. Clinical data show that the user's deep sleep time increases by an average of 23 minutes.

The emergence of bamboo fiber Tencel quilt is not only the advent of a new type of bedding, but also the embodiment of modern people's pursuit of high-quality life. It perfectly interprets the harmonious unity of technology and nature, and provides an ideal choice for consumers who pursue a healthy and environmentally friendly lifestyle. With the enhancement of people's environmental awareness and the improvement of their quality of life, this bedding that combines innovative technology and natural wisdom will surely lead the new trend of future home life.

En

En  Français

Français Deutsch

Deutsch عربى

عربى

+86-18268324012

+86-18268324012 +86-573-88798908

+86-573-88798908 Iris@zjmkn.com

Iris@zjmkn.com 233 Huashi East Road, Wuzhen Town, Tongxiang City, Jiaxing, Zhejiang Province, China

233 Huashi East Road, Wuzhen Town, Tongxiang City, Jiaxing, Zhejiang Province, China