The irregular elliptical pore structure on its surface is the key to its strong air permeability and moisture absorption. In-depth exploration of the intrinsic connection between this microstructure and fiber performance can make us clearly understand the root of viscose bamboo fiber's excellent performance in practical applications.

Looking closely at viscose bamboo fiber from a microscopic perspective, the irregular elliptical pores on its surface are not randomly distributed, but follow specific rules. These pores vary in size and maintain a subtle spacing between each other. The irregular shape of the pores allows the fiber surface to form a rich concave and convex structure, which fundamentally changes the interaction mode between the fiber and the external environment.

To understand the uniqueness of viscose bamboo fiber pores, it is necessary to trace its formation process. Complex physical and chemical processing processes play an important role in processing bamboo into viscose bamboo fiber. The original tissue structure of bamboo is reconstructed during the processing process, and the cellulose molecules are rearranged and combined under specific process conditions, thus forming this irregular elliptical pore structure. This process not only retains some of the natural characteristics of bamboo, but also creates a microscopic form that is conducive to air permeability and moisture absorption through artificial intervention.

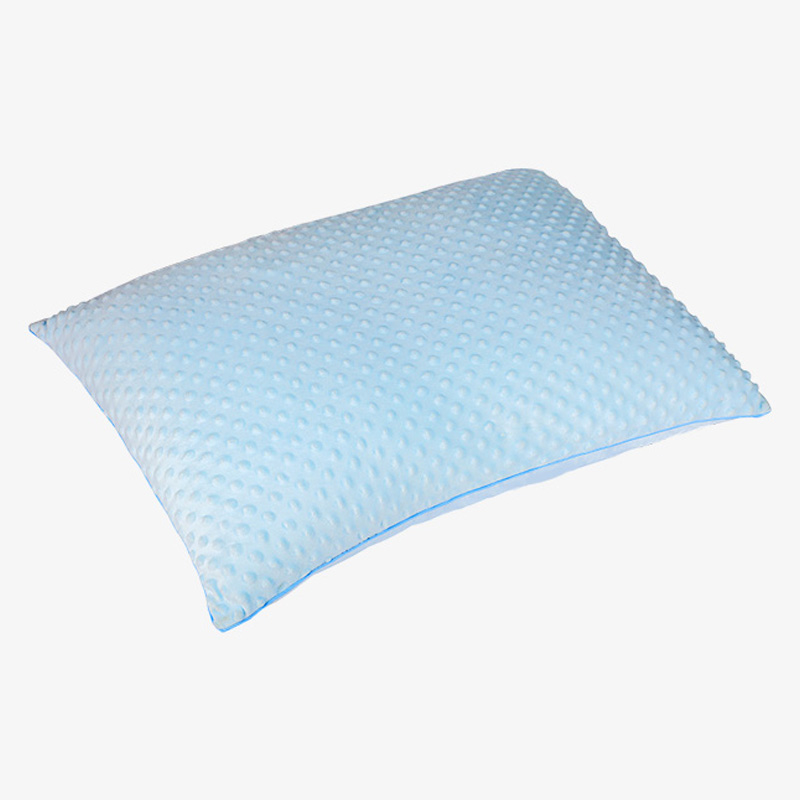

In terms of air permeability, these irregular elliptical pores are irreplaceable. When the outside air comes into contact with viscose bamboo fiber, the pores are like carefully designed air channels. Unlike ordinary fibers with tight structures and lack of effective air permeability channels, viscose bamboo fiber greatly reduces air circulation resistance with the unique space constructed by pores. Taking the sleeping scene as an example, the human body will continue to emit body heat during sleep, and the hot air mass formed by this heat will diffuse to the surroundings. The pores on the surface of the viscose derived bamboo mattress cover quickly take effect, and the hot air mass can quickly enter the pores, transfer the heat to the outside of the fiber through the connecting channels between the pores, and finally dissipate into the air. Due to the lack of efficient air permeability structure of ordinary fibers, heat is easily accumulated between the fiber and the skin, resulting in a stuffy feeling and affecting sleep comfort.

The irregular shape of the pores in viscose bamboo fiber brings additional advantages. The irregular shape makes the air flow path inside the pores complex and changeable. The air constantly collides and turns in the pores, increasing the contact area with the inside of the fiber. This complex flow mode greatly promotes the heat exchange between air and fiber, further improving the breathability effect. When the external ambient temperature is low, the external cold air can also enter the fiber through the pores, exchange heat with the internal fiber, and achieve a dynamic balance between the fiber temperature and the external ambient temperature, so that users can maintain a comfortable body feeling under different temperature environments. Compared with some common chemical fibers, the surface of chemical fibers is relatively smooth and flat, and the air circulation is limited, making it difficult to achieve such efficient heat exchange. It is far inferior to viscose bamboo fiber in temperature regulation.

Looking at the hygroscopicity, the irregular elliptical pores of viscose bamboo fiber also play a core role. Water molecules have surface tension and adsorption characteristics. When human sweat contacts the surface of viscose bamboo fiber, the pores provide a strong adsorption site for water molecules. The inner wall of the pore has a special surface energy, which can form a strong intermolecular force with water molecules. This force prompts water molecules to quickly attach to the inner wall of the pore and penetrate into the fiber along the pore. Due to the irregular size and shape of the pores, water molecules will form a complex distribution inside the pores after entering them. Smaller pores have a stronger binding force on water molecules, making them firmly adsorbed; larger pores provide space for water molecules to store and diffuse.

As water molecules are continuously adsorbed by the pores, the moisture inside the viscose bamboo fiber gradually increases. The connectivity between the pores begins to play a role, and water molecules can diffuse and transfer inside the fiber through the tiny channels between the pores. This diffusion process allows the moisture to be evenly distributed inside the fiber to avoid local moisture. When the humidity of the external environment is low, the water molecules inside the fiber will gradually diffuse to the outside through the pores to release moisture. This dynamic balance process of adsorption-diffusion-release enables viscose bamboo fiber to automatically adjust its own moisture content according to the changes in the humidity of the external environment, always maintain humidity balance with the external environment, and provide users with a dry touch. Compared with wool fiber, although wool also has a certain degree of hygroscopicity, the structure of wool fiber is different from that of viscose bamboo fiber. Its hygroscopicity mainly depends on the fiber scale structure. In terms of moisture diffusion and release speed, viscose bamboo fiber has more advantages.

From the perspective of the overall fiber structure, the presence of irregular elliptical pores significantly changes the specific surface area of viscose bamboo fiber. The increase in specific surface area means that the contact area between the fiber and the external substance increases, which is not only conducive to air circulation, but also enhances the fiber's ability to adsorb water molecules. The larger contact area allows the fiber to adsorb more water molecules in a shorter time, while accelerating the diffusion rate of water molecules inside the fiber. In actual use, when the human body sweats a lot, viscose bamboo fiber can quickly absorb sweat and minimize the feeling of moisture.

In actual production applications, different production process parameters will also affect the pore structure of viscose bamboo fiber. For example, factors such as temperature, pressure and chemical reagent concentration during the processing process will change the size, shape and distribution density of the pores. Manufacturers continuously adjust these parameters to optimize the pore structure, thereby producing viscose bamboo fibers with better performance. These optimized fibers are widely used in various home textile products, from mattress covers to sheets and quilt covers, bringing consumers a more comfortable use experience.

How do the irregular elliptical pores of viscose bamboo fiber give it strong air permeability and moisture absorption?

En

En  Français

Français Deutsch

Deutsch عربى

عربى

+86-18268324012

+86-18268324012 +86-573-88798908

+86-573-88798908 Iris@zjmkn.com

Iris@zjmkn.com 233 Huashi East Road, Wuzhen Town, Tongxiang City, Jiaxing, Zhejiang Province, China

233 Huashi East Road, Wuzhen Town, Tongxiang City, Jiaxing, Zhejiang Province, China