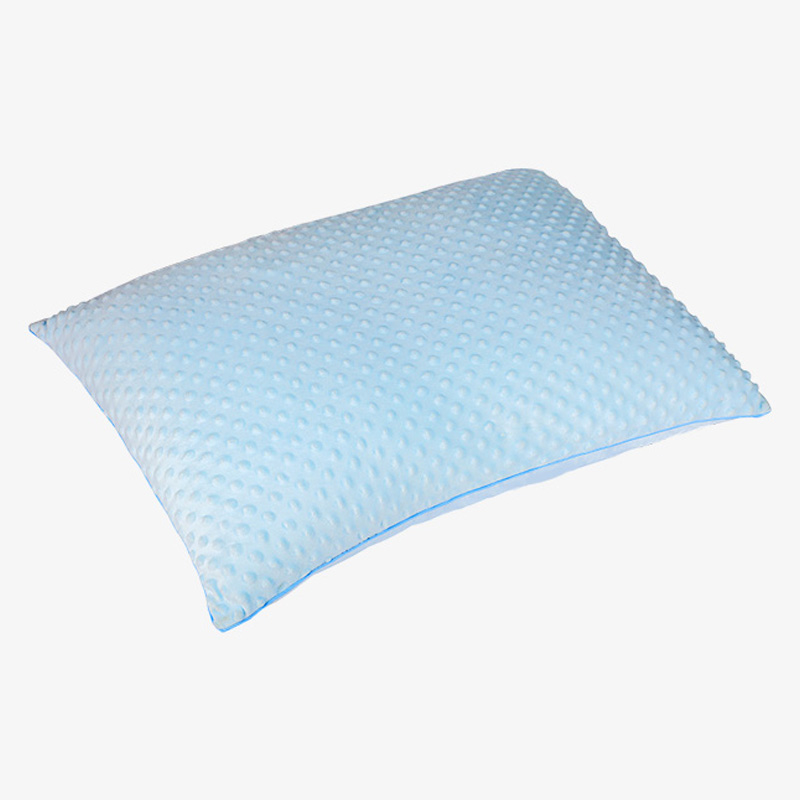

Natural latex is taken from the sap of rubber trees. It is a viscous milky white liquid. Its pure natural properties lay a good foundation for temperature controlled mattress pad. However, the newly collected latex cannot be used directly for mattress making. It needs to be filtered and treated to remove possible impurities, ensure the purity of the raw materials, and prepare for subsequent processes.

The foaming process is the key step to transform latex into a form suitable for mattress use. In this process, professional equipment mixes air evenly into the latex. By precisely controlling parameters such as temperature, time and stirring speed during the foaming process, a fine and uniform pore structure is formed inside the latex. Different foaming temperatures will have a significant impact on the formation of latex pores. At lower temperatures, the fluidity of latex is relatively weak, and the pores formed are relatively small and dense; when the temperature is slightly higher, the fluidity of latex is enhanced, and the pores will be larger. The stirring speed is also important. If the speed is too fast, the bubbles in the latex may be uneven in size, affecting the quality of the final product; if the speed is too slow, the air cannot be fully mixed in, and the ideal foaming effect cannot be achieved. These pores give the latex a light texture and greatly improve its breathability. When people lie on a temperature-controlled mattress, air can flow freely in the pores of the latex, and the heat and moisture discharged by the human body can be quickly dissipated, avoiding the impact of hot and humid conditions on sleep quality. Moreover, these evenly distributed pores can also make the latex disperse pressure more evenly when it is stressed, providing comfortable support for the body. When people of different weights lie on the latex layer, the pores will deform adaptively according to the pressure, which will not make people with lighter weight feel that the mattress is too hard, but also provide sufficient support for people with heavier weight.

After the foaming is completed, the latex enters the vulcanization stage. Vulcanization is to induce cross-linking reactions in latex molecules under specific temperature and pressure conditions, thereby changing the physical and chemical properties of latex. The vulcanization process is usually divided into low-temperature vulcanization, medium-temperature vulcanization and high-temperature vulcanization. Different vulcanization temperatures and time settings will make latex present different performance characteristics. Low-temperature vulcanization takes a relatively long time, which can slowly and fully cross-link the latex molecules, making the latex elasticity softer and suitable for users who have high requirements for the softness of the mattress; high-temperature vulcanization can complete molecular cross-linking in a shorter time, and the obtained latex has higher hardness and resilience, which is more suitable for people who need stronger support. During the vulcanization process, the molecular structure of latex becomes more compact and orderly from the original relatively loose state, which significantly improves the elasticity and durability of latex. The vulcanized latex has better resilience. When the human body lies on the mattress, it can quickly fit the body curve and provide precise support to the body; when the human body leaves the mattress, it can quickly return to its original state, ensuring that the mattress is not easily deformed during long-term use. This good elasticity can not only effectively relieve the pressure on various parts of the body and reduce the number of turning over during sleep, but also provide good support for the spine, maintain the natural physiological curve of the spine, and reduce the risk of back pain caused by improper sleeping posture.

The latex layer made through the foaming and vulcanization process plays an important role in many aspects of the temperature-controlled mattress. In terms of temperature regulation, the good air permeability of latex itself complements the intelligent temperature control system of the temperature-controlled mattress. When the temperature control system adjusts the temperature of the mattress, the pore structure of the latex can accelerate the conduction and dissipation of heat, so that the temperature is more evenly distributed on the surface of the mattress. Whether it is turning on the heating function in the cold winter or starting the cooling mode in the hot summer, the latex layer can assist the temperature control system and let users feel the comfortable temperature faster. When heating in winter, the heat can be quickly transferred to the contact part of the human body through the pores of the latex, and there will be no local overheating or overcooling; when cooling in summer, the heat generated by the human body can also be quickly dissipated through the pores to maintain the coolness of the mattress surface.

From the perspective of comfort, the soft touch of latex and the moderate support force are perfectly combined to bring users the ultimate sleeping experience. Its delicate texture fits the skin, reduces the friction between the body and the mattress, and makes people feel as comfortable as sleeping on the clouds. For users of different weights and body shapes, the latex layer can be adaptively adjusted according to the body pressure, evenly disperse the pressure, avoid excessive local pressure, and ensure the comfort and relaxation of sleep. When sleeping on the side, the latex layer can effectively buffer the pressure of the shoulders and hips to prevent soreness; when lying on the back, it can provide just the right support for the waist to prevent the waist from hanging in the air.

In terms of health protection, natural latex itself has anti-mite and antibacterial properties, and this advantage is still retained after foaming and vulcanization. It is difficult for mites and bacteria to survive and reproduce in the structure of latex, creating a healthy and hygienic sleeping environment for users. Especially for people with sensitive skin or respiratory diseases, this anti-mite and antibacterial function can effectively reduce the risk of allergies and infections and protect the health of users. At the same time, the natural material of latex does not release harmful chemicals, and it will not cause harm to human health even if used for a long time.

The presence of the latex layer also enhances the overall durability of the temperature-controlled mattress. Due to its good elasticity and resilience, the latex layer can withstand the pressure of the human body without being easily damaged during long-term use, reducing the possibility of mattress deformation and collapse, and extending the service life of the temperature-controlled mattress. At the same time, the chemical properties of latex are relatively stable and are not easily affected by external environmental factors and aged and deteriorated, further ensuring the stability of the mattress quality. Even in a humid environment, latex will not easily mold and deteriorate, and can still maintain good performance.

How does latex shape the quality of Temperature Controlled Mattress Pad after foaming and vulcanization?

En

En  Français

Français Deutsch

Deutsch عربى

عربى

+86-18268324012

+86-18268324012 +86-573-88798908

+86-573-88798908 Iris@zjmkn.com

Iris@zjmkn.com 233 Huashi East Road, Wuzhen Town, Tongxiang City, Jiaxing, Zhejiang Province, China

233 Huashi East Road, Wuzhen Town, Tongxiang City, Jiaxing, Zhejiang Province, China