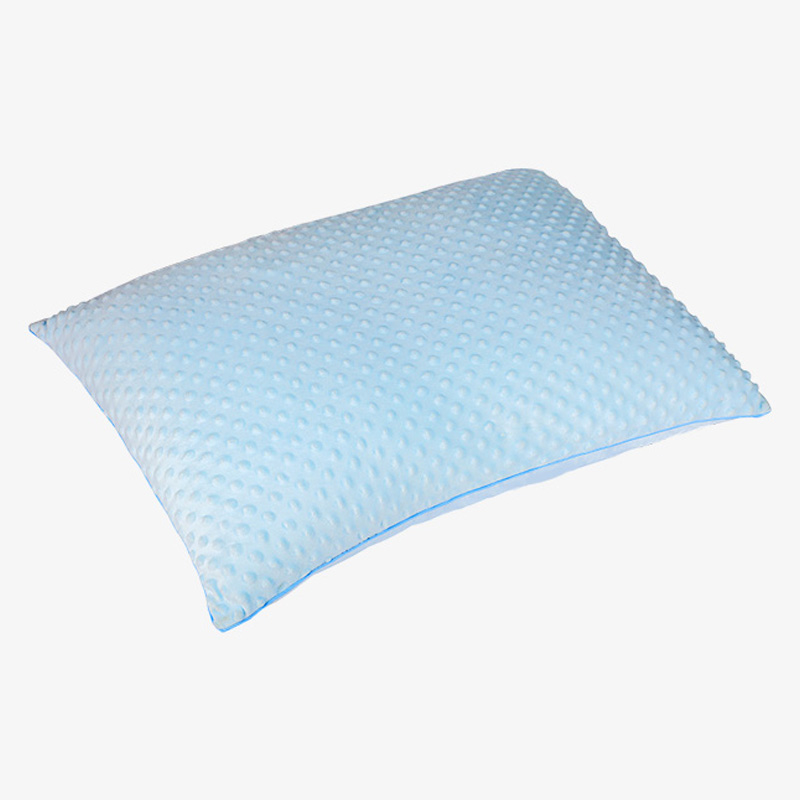

In the competitive landscape of home textiles, the white duvet comforter queen remains a cornerstone of inventory for retailers, hospitality groups, and wholesalers. Its versatility in design and universal appeal make it a high-demand item, yet sourcing a product that balances aesthetics with structural integrity requires a deep technical understanding. Selecting the right bedding involves more than just thread count; it requires an analysis of fill power, shell construction, and the specific performance requirements of the end-user. As manufacturers innovate to meet the rising demand for healthier sleeping environments, the criteria for selecting premium bedding have evolved, prioritizing durability, hygiene, and thermal regulation.

Established in 2008 and located in Wuzhen, Tongxiang, Zhejiang Province, China, Moncanol has established itself as a premier manufacturer in this sector, focusing on the production of moisture-wicking, dust mite resistant, anti-bacterial, and eco-friendly products. With a robust R&D capability, Moncanol develops more than 3,000 new products annually, ranging from comforters and pillows filled with bamboo, cotton, Tencel, polyester, and silk, to mattress pads and waterproof protectors. The company’s commitment to quality is rigorous; its QC department controls the process from raw materials to finished products, ensuring that every item meets stringent standards. This dedication allows Moncanol to deliver quality and quantity at the right price, helping clients grow and progress in a dynamic market.

The global bedding industry is currently undergoing a significant transformation driven by technological advancements in fiber engineering and sustainable manufacturing. According to the "Home Textile Market Review 2024" by the International Sleep Products Association (ISPA), the demand for bedding solutions that offer thermal regulation and hypoallergenic properties is accelerating, with consumers increasingly prioritizing performance materials over traditional fillings. This shift underscores the necessity for buyers to evaluate the technical specifications of comforters—such as fiber type and construction quality—to ensure they meet contemporary consumer expectations for health and comfort.

Source: International Sleep Products Association (ISPA)

Determining the Ideal Fill Material and Warmth Level

The heart of any comforter lies in its filling, which dictates the warmth, weight, and overall tactile experience. When procuring a white duvet comforter queen, buyers must weigh the benefits of natural fills against the consistency and cost-efficiency of synthetic fibers. While down is prized for its insulation-to-weight ratio, synthetic alternatives have made significant strides in mimicking these properties while offering superior hypoallergenic performance and ease of care. For commercial environments such as hotels or hospitals, where frequent laundering is required, the resilience of synthetic fills often makes them the more pragmatic choice.

- Natural Down: Offers superior loft and breathability but requires higher maintenance and can trigger allergies.

- Synthetic Fibers: Provide consistent warmth, are generally hypoallergenic, and retain their insulating properties even when damp.

- Fill Power: A measure of loft; higher fill power indicates better insulation (trap more air with less weight).

- Weight Classifications: Ranging from ultra-light for summer to heavyweight for winter use.

Analyzing White Down Alternative Comforter Options

The white down alternative comforter has emerged as a dominant force in the B2B market, particularly for clients seeking the plushness of down without the associated allergens. These alternatives typically utilize advanced polyester gel fibers or cluster fibers that are engineered to mimic the clustering structure of natural down clusters. This engineering allows the fill to trap heat effectively while maintaining a fluffy, uniform appearance. For manufacturers like Moncanol, utilizing advanced fiber technology ensures that the white down alternative comforter remains resilient after repeated industrial washing, a critical factor for hospitality procurement where longevity is directly tied to ROI.

The Benefits of a Lightweight White Comforter Queen

While warmth is essential, the market has seen a surge in demand for the lightweight white comforter queen. This product category is essential for year-round use and climates with milder winters. The technical advantage of a lightweight option lies in its breathability; lighter fills allow for better airflow, preventing the sleeper from overheating. For hotel chains looking to offer a "four-season" bedding solution, a lightweight white comforter queen can be layered during colder months or used alone in summer, offering versatility and reducing the need for separate inventory SKUs.

| Feature | Lightweight Comforter | Heavyweight Comforter |

| Fill Weight | Low density (approx. 20-30 oz for Queen) | High density (40+ oz for Queen) |

| Breathability | High; excellent for heat dissipation. | Lower; designed to maximize heat retention. |

| Best Use Case | Summer use, layering, warm climates. | Winter use, cold climates, drafty rooms. |

| Laundering Efficiency | Dries faster, reducing energy costs in commercial laundry. | Takes longer to dry; requires higher capacity machines. |

Fabric Shell Construction and Thread Count

The durability of a white duvet comforter queen is heavily reliant on the quality of its shell fabric. The shell serves as the barrier that contains the fill and must withstand friction and abrasion. While thread count is often marketed as a primary quality indicator, the weave type and the grade of the raw fiber are arguably more critical for performance. A high thread count with a tight weave prevents the fill from migrating (leaking) through the fabric. For white bedding, the shell must also possess a high degree of whiteness retention to resist yellowing over time.

- Material Composition: 100% cotton is preferred for breathability, while cotton-polyester blends offer higher durability and wrinkle resistance.

- Weave Density: A tight cambric or sateen weave is essential to prevent down or fiber leakage.

- Finishing: Sanforization (pre-shrinking) and calendering ensure the fabric remains smooth and dimensionally stable.

- Yarn Quality: Long-staple cotton fibers produce a smoother, stronger fabric than short-staple alternatives.

Why Thread Count Matters Less Than Weave Type for Hotel Quality White Comforter

In the context of hotel quality white comforter manufacturing, the emphasis often shifts from thread count to fabric strength and finish. Hotels require linens that can withstand high-temperature commercial laundering and frequent use. A hotel quality white comforter often utilizes a durable down-proof fabric, usually with a thread count between 200 and 400, which balances breathability with leak prevention. Extremely high thread counts (800+) can sometimes be too tight, reducing the breathability of the comforter and making it feel stiff or "boardy," which reduces guest comfort. Therefore, Moncanol prioritizes specialized weaves that offer superior tensile strength and a soft hand-feel, ensuring the hotel quality white comforter withstands the rigors of professional hospitality environments.

td>Softener focus for initial hand-feel. td>Sanforized and mercerized for shrinkage and stain resistance.

| Fabric Attribute | Standard Consumer Comforter | Hotel Quality Comforter |

| Thread Count | Often marketed very high (300-1000 TC). | Optimized for durability (200-400 TC). |

| Weave Structure | Standard plain weave; may loosen over time. | High-density down-proof weave; tighter lockstitch. |

| Finish |

Advanced Features for Sleep Climate Regulation

Temperature regulation is a key differentiator in the modern bedding market. Sleepers often struggle with overheating, a problem that manufacturers address through moisture-wicking technologies. By integrating fibers that draw moisture away from the skin and expel it into the atmosphere, the comforter maintains a dry, comfortable microclimate. This is particularly important for cooling white duvet insert products designed for hot sleepers or warmer climates.

- Moisture Wicking: Capabilities of the fill to transport sweat away from the body.

- Thermal Conductivity: How quickly heat passes through the material; cooling fibers increase this rate.

- Ventilation: The incorporation of breathable channels or mesh panels in the shell design.

- Phase Change Materials (PCM): Advanced materials that absorb, store, and release heat for optimal temperature control.

Utilizing Cooling White Duvet Insert Technology

The cooling white duvet insert represents the intersection of textile engineering and sleep science. Unlike traditional comforters that merely trap air, cooling inserts are filled with specialized fibers—such as specially treated polyester, bamboo, or Tencel—that possess high thermal conductivity. These fibers actively conduct body heat away from the sleeper. Furthermore, the shell fabric of a cooling white duvet insert is often treated with hydrophilic finishes to enhance moisture wicking. For B2B buyers targeting warm geographical markets or luxury eco-conscious segments, offering a cooling technology solution is no longer optional but a necessity for a competitive product portfolio.

td>Retains body heat. td>Dissipates body heat and moisture.

| Technology | Standard Comforter | Cooling White Duvet Insert |

| Fill Type | Standard polyester or down (insulative focus). | Gel fiber, bamboo, or Tencel (conductive/wicking focus). |

| Heat Management | ||

| Best For | Cold environments and users who feel cold easily. | Hot sleepers, summer use, and heated bedrooms. |

Construction Techniques: Baffle Box vs. Sewn-Through

The internal construction of the comforter dictates how the fill is distributed and maintained. The two primary methods are sewn-through (or box stitch) and baffle box construction. Sewn-through construction involves stitching the top and bottom layers of fabric together directly, creating distinct pockets. This is cost-effective and ensures the fill stays in place, but the stitching compresses the fill at the seams, creating cold spots. In contrast, baffle box construction uses internal fabric walls (baffles) to connect the shell layers. This allows the fill to loft to its maximum potential, creating a flatter, more insulating layer without cold spots.

- Sewn-Through: Simple construction, prevents shifting, but reduces loft at seams.

- Baffle Box: Internal walls allow maximum loft and uniform warmth.

- Ring Stitch: A compromise where stitches are spaced far apart; requires internal ties.

- Corner Tabs: Essential for securing the duvet inside a cover and preventing shifting.

Comparing Durability and Aesthetic Flatness in Queen-Sized Bedding

For a queen-sized bed, maintaining the aesthetic flatness of the bedding is crucial for visual appeal. Baffle box construction generally yields a higher-end look because the comforter appears puffier yet sits flatter on the bed, as the fill is allowed to expand vertically rather than bulging unevenly. Sewn-through comforters tend to have a more "quilted" appearance, which can look dimpled. For a white duvet comforter queen intended for luxury retail or high-end hospitality, the baffle box design is often preferred to maximize the thermal efficiency and visual volume of the bedding, ensuring the bed looks impeccably made and inviting.

td>Generally more economical. td>Higher manufacturing cost and complexity.

| Construction Type | Sewn-Through | Baffle Box |

| Warmth Efficiency | Good for light warmth; cold spots at seams. | Excellent; eliminates cold spots via lofted baffles. |

| Weight Distribution | Fill is locked in place securely. | Fill can move slightly within the box; needs good internal baffles. |

| Cost |

Care, Maintenance, and Longevity for Commercial Use

For B2B clients, the lifecycle cost of a comforter is as important as the initial purchase price. White comforters, by their nature, are prone to visible staining. Therefore, selecting products with easy-care properties is vital. This includes pre-shrunk fabrics that can withstand industrial washing temperatures and dyes that are colorfast. The use of anti-microbial and anti-bacterial treatments, such as those employed by Moncanol, extends the usable life of the product by preventing the degradation of fibers caused by bacteria and mold, ensuring the white duvet comforter queen remains pristine over time.

- Machine Washable: Must fit in standard commercial washers (typically 60lbs+ capacity).

- Drying: Must dry efficiently to prevent energy waste and mold growth.

- Stain Resistance: Treated fabrics to repel oil and water-based stains.

- Durability: Reinforced stitching (double needle or serged edges) to prevent fraying.

Conclusion

Choosing the right white duvet comforter queen is a multifaceted decision that requires balancing material science with the practical needs of the end-user. Whether opting for the hypoallergenic resilience of a white down alternative comforter, the year-round versatility of a lightweight white comforter queen, or the advanced engineering of a cooling white duvet insert, buyers must prioritize quality construction and fill integrity. By partnering with experienced manufacturers like Moncanol, who adhere to strict QC protocols from raw materials to finished goods, businesses can ensure they offer products that deliver on comfort, durability, and aesthetic value. Ultimately, investing in high-quality materials—such as hotel quality white comforter standards—ensures customer satisfaction and long-term brand reputation in a competitive marketplace.

FAQ

What is the difference between a duvet insert and a comforter?

Functionally, a white duvet comforter queen used as an insert and a comforter are very similar; both provide insulation. The primary difference lies in usage. A duvet insert is designed to be placed inside a removable duvet cover, often with corner tabs to secure it. A comforter is typically used as-is, often featuring a decorative pattern or color. Since we are discussing white options, they are often interchangeable, but "insert" implies the need for a separate cover.

Why is a down alternative comforter better for commercial use?

A white down alternative comforter is generally preferred in commercial settings like hotels and hospitals because it is hypoallergenic, easier to clean, and more durable than natural down. Synthetic fibers like those used by Moncanol are designed to withstand frequent industrial washing and high-heat drying without losing their loft or shape, ensuring a longer service life and consistent guest experience.

Can a lightweight comforter provide enough warmth?

Yes, a lightweight white comforter queen is designed for breathability and versatility. It provides sufficient insulation for standard sleeping environments and warmer seasons. Its primary benefit is that it prevents overheating, making it ideal for sleepers who find heavy bedding restrictive. In cooler weather, it can easily be layered with blankets to adjust the warmth level.

How do I know if a comforter is "hotel quality"?

A hotel quality white comforter is defined by its durability, construction, and fill consistency. Look for features like high thread count, down-proof fabric (usually 100% cotton), and baffle box or box stitch construction that prevents shifting. Hotel quality also implies a crisp white finish and a rigorous pre-washing process to ensure the product is dimensionally stable and immediately usable upon purchase.

What makes a cooling duvet insert different from a regular one?

A cooling white duvet insert utilizes advanced materials—such as moisture-wicking fibers (Tencel or Bamboo) or gel-infused polyester—that conduct heat away from the body and allow higher airflow. While regular comforters focus on trapping heat, a cooling insert prioritizes thermal regulation to maintain a neutral temperature, specifically targeting hot sleepers or warm climates.

En

En  Français

Français Deutsch

Deutsch عربى

عربى

+86-18268324012

+86-18268324012 +86-573-88798908

+86-573-88798908 Iris@zjmkn.com

Iris@zjmkn.com 233 Huashi East Road, Wuzhen Town, Tongxiang City, Jiaxing, Zhejiang Province, China

233 Huashi East Road, Wuzhen Town, Tongxiang City, Jiaxing, Zhejiang Province, China